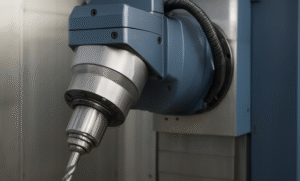

A winkelbohrspindel is a specialised drilling tool designed to provide precision in tight or angled spaces where standard drills cannot reach. Its unique design allows the drill rotation to be redirected using bevel gears, typically at 90 degrees, making it ideal for complex machining, woodworking, and metalworking tasks. The tool’s versatility has made it an essential piece of equipment in professional workshops across the UK and beyond.

Using a winkelbohrspindel improves both accuracy and efficiency, allowing operators to work in confined areas without repositioning the workpiece. This not only reduces errors but also saves significant time during production. Modern models offer a variety of attachments and adjustable angles, ensuring that both hobbyists and professionals can achieve precise results with minimal effort.

What is a Winkelbohrspindel

A winkelbohrspindel, or angle drilling spindle, is designed to redirect the rotational axis of a drill or milling tool. Unlike conventional spindles, it enables drilling at challenging angles, often 90 degrees, without requiring the operator to reposition the material. This makes it especially useful for machinery, cabinetry, and metal fabrication, where precision and accessibility are critical.

The construction of a winkelbohrspindel emphasises durability, with high-quality steel and aluminium components. Bevel gears ensure smooth torque transfer and stable rotation, even under heavy loads. By combining flexibility with strength, a winkelbohrspindel becomes an indispensable tool for workshops that need to maintain efficiency while performing precise angle drilling.

Key Features and Specifications of Winkelbohrspindel

Modern winkelbohrspindeln offer a range of features designed for maximum performance. High torque and variable spindle speeds allow them to handle different materials, from soft wood to hardened metals. Drill diameter compatibility ensures that operators can use various sizes without switching tools, while adjustable angles provide added flexibility for complex projects.

Many models come with interchangeable adapters, allowing compatibility with multiple machines and drill types. Both pneumatic and electric versions are available, catering to different operational needs. The combination of robust construction, precise gearing, and versatile compatibility makes the winkelbohrspindel a highly reliable tool for both industrial and DIY use.

Applications of Winkelbohrspindel

Winkelbohrspindeln are widely used across industries for tasks that require angled drilling or milling. In automotive and aerospace manufacturing, they provide access to areas where standard drills cannot reach, enabling precise assembly and modifications. Metalworking industries rely on them for accurate machining in tight spaces, where misalignment could result in costly errors.

For woodworking and cabinetry, a winkelbohrspindel allows for angled holes in furniture and fixtures without complex jigs. Hobbyists and small workshops also benefit from its versatility, as it simplifies challenging projects and improves accuracy. Its application extends from professional production lines to DIY enthusiasts seeking professional results in home workshops.

Benefits of Winkelbohrspindel

The primary benefit of a winkelbohrspindel is enhanced precision. Drilling at difficult angles becomes straightforward, reducing material waste and ensuring consistent results. Its design allows operators to work more efficiently, particularly in confined areas where standard drills are impractical. This combination of precision and speed makes it an invaluable tool in any professional or home workshop.

A winkelbohrspindel also offers versatility, handling various drill sizes and materials with ease. Ergonomic designs minimise operator fatigue during prolonged use, and the tool’s durability ensures a long operational life. By improving both efficiency and safety, a winkelbohrspindel represents a smart investment for anyone involved in detailed woodworking, metal fabrication, or industrial machining.

How to Choose the Right Winkelbohrspindel

Selecting the right winkelbohrspindel depends on your specific project requirements. Consider factors such as drill diameter compatibility, torque capacity, and angle flexibility. High-quality materials and reputable brands provide reliability and longevity, while adjustable models allow greater versatility for diverse tasks. Assessing these features ensures you invest in a tool that meets both immediate and future needs.

Compatibility with existing machines is also crucial. Some winkelbohrspindeln come with universal adapters, while others are designed for specific spindle mounts. Evaluating workshop setup, frequency of use, and project complexity helps determine the best choice. By carefully considering these factors, you can ensure maximum efficiency and precise results across multiple applications.

Maintenance and Best Practices for Winkelbohrspindel

Proper maintenance of a winkelbohrspindel is essential for long-term performance. Regular cleaning, lubrication, and inspection prevent wear and ensure smooth operation. Checking adapters, tightening screws, and avoiding overload during use help preserve both accuracy and safety, extending the tool’s lifespan significantly.

Safe handling and storage are also critical. Keeping the winkelbohrspindel in a dry, secure environment protects its components from damage. Following manufacturer guidelines for maintenance and use ensures that the spindle continues to deliver precision, reliability, and efficiency for every project, whether in a professional or home workshop.

Conclusion

A winkelbohrspindel is a versatile and indispensable tool for modern drilling and machining applications. Its ability to perform precise angle drilling in tight spaces improves workflow, accuracy, and efficiency across multiple industries. By choosing the right model and maintaining it properly, operators can ensure long-term performance and high-quality results for every project.

Investing in a winkelbohrspindel can transform workshop operations, offering enhanced precision and reliability. Whether for professional manufacturing, metalworking, or woodworking, this tool provides consistent, accurate results that elevate both productivity and craftsmanship.

You may also read: UK Property Tax Guide on Rental Income