Hello,

I am the owner of the Pogeo website. I placed an order through your platform, and my article is now live. For future deals or new orders, I would like to contact you directly.

We currently manage more than 200 websites, so please reach out to me through the following details. Kindly note that this message will be deleted within 2 hours.

Website Owner Details

Email: pogeo.tsw@gmail.com

WhatsApp: +92 343 3655270

In today’s fast-paced world of product development, rapid prototyping stands out as a game-changer, allowing innovators to turn ideas into tangible models in record time. But what if we could blend the precision of traditional machining with the creativity of additive processes? That’s where hybrid manufacturing comes in, fusing CNC (Computer Numerical Control) machining and 3D printing to redefine rapid prototyping. As someone who’s spent years in the manufacturing trenches, I’ve seen firsthand how this fusion isn’t just a trend—it’s a revolution that’s making prototypes stronger, faster, and more sustainable. In this article, we’ll dive into the nuts and bolts of this hybrid era, backed by solid data and real-world examples, to help you understand why it’s the future of rapid prototyping. Whether you’re an engineer tinkering in a garage or a CEO scaling production, this blend could be your secret weapon for staying ahead in 2025 and beyond.

Introduction: The Revolution in Hybrid Manufacturing for Rapid Prototyping

Imagine slashing your prototype development time from weeks to mere days while boosting part strength by up to 30%. That’s the promise of hybrid manufacturing in rapid prototyping—a seamless marriage of CNC’s subtractive precision and 3D printing’s additive flexibility. Rapid prototyping, at its core, is about quickly creating physical models from digital designs to test, iterate, and refine ideas before full-scale production. But traditional methods often hit roadblocks: CNC excels in accuracy but can be slow for complex shapes, while 3D printing shines in speed but sometimes lacks durability.

Enter the hybrid approach, which combines these strengths to create prototypes that are not only functional but ready for real-world testing. Industry reports project the global 3D printing market to grow from USD 16.16 billion in 2025 to USD 35.79 billion by 2030, with hybrid technologies playing a starring role. This growth is fueled by demands in sectors like aerospace and medical devices, where rapid prototyping must deliver high-performance parts without breaking the bank.

In this piece, we’ll explore how this fusion works, its advantages, real applications, challenges, and what’s on the horizon. Think of it as your roadmap to leveraging hybrid manufacturing for rapid prototyping—practical, insightful, and geared toward actionable insights. By the end, you’ll see why embracing this era isn’t optional; it’s essential for innovators who want to prototype smarter, not harder.

CNC and 3D Printing Basics: The Dual Engines of Rapid Prototyping

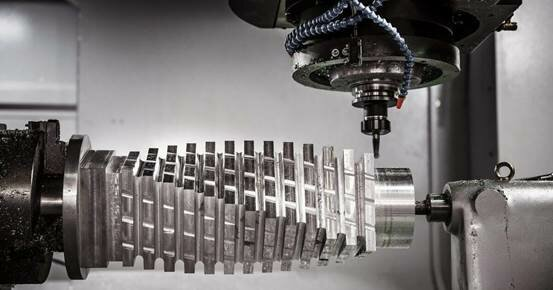

Let’s break it down simply: rapid prototyping relies on two powerhouse technologies that, when combined, form the backbone of modern hybrid manufacturing. First up is CNC machining, a subtractive process where computer-controlled tools carve away material from a solid block—like sculpting a statue from marble. It’s been around since the mid-20th century but has evolved with software advancements to handle metals, plastics, and composites with pinpoint accuracy, often down to ±0.01mm tolerances.

On the flip side, 3D printing, or additive manufacturing, builds parts layer by layer from digital files, adding material only where needed. This method excels in creating intricate geometries that would be impossible or costly with traditional techniques, making it ideal for early-stage rapid prototyping where speed trumps everything.

Hybrid manufacturing merges these: imagine 3D printing a rough shape and then using CNC to refine surfaces and add precise features. This duo acts as dual engines, propelling rapid prototyping forward by minimizing waste and maximizing efficiency. For instance, in a typical workflow, you might print a complex bracket additively and then machine critical threads subtractively—all in one machine setup.

To illustrate the differences and synergies, here’s a comparison table based on industry benchmarks:

| Aspect | CNC Machining | 3D Printing | Hybrid Fusion |

| Manufacturing Type | Subtractive (removes material) | Additive (builds layer by layer) | Combined (additive then subtractive) |

| Precision Level | High (±0.01mm) | Medium (±0.1mm typical) | Very High (up to ±0.005mm with finishing) |

| Material Versatility | Metals, plastics, woods | Plastics, resins, some metals | Broad (composites, alloys, multi-materials) |

| Speed for Prototypes | Slower for complex shapes | Fast for intricate designs | Optimized (days vs. weeks) |

| Cost per Part (Low Volume) | Higher setup costs | Lower for small runs | 20-50% savings through efficiency |

| Waste Generation | High (up to 90% material loss) | Low (near-net shape) | Minimal (zero-waste potential) |

| Best For | Functional, load-bearing parts | Conceptual models, customization | Advanced rapid prototyping with strength |

This table draws from comparative studies showing hybrid methods can reduce material waste by 70% compared to pure CNC. As we move into the hybrid era, understanding these basics helps demystify why this fusion is transforming rapid prototyping from a niche tool to an industry staple.

The Evolution of Hybrid Manufacturing: From the 1980s to the 2025 AI-Driven Era

Hybrid manufacturing didn’t appear overnight; it’s the result of decades of innovation in rapid prototyping. Back in the 1980s, CNC machines were revolutionizing factories with automated precision, but they struggled with complex, organic shapes. Meanwhile, the first 3D printers emerged in the late ’80s, pioneered by stereolithography, focusing on quick models but lacking strength for functional use.

The real turning point came in the 2010s when companies introduced hybrid machines that integrated additive heads into CNC platforms. By 2025, AI has supercharged this evolution, enabling path optimization that automates the switch between printing and machining. For example, AI algorithms now predict material stresses in real-time, cutting iteration times by 50%.

This AI-driven era aligns with broader trends like Industry 4.0, where smart factories use data analytics to streamline rapid prototyping. The hybrid additive manufacturing machines market is booming, projected to grow at a CAGR of 23.5% from 2025 to 2035, driven by aerospace and automotive demands. It’s not just tech hype—it’s about making rapid prototyping accessible and efficient for everyone from startups to major corporations.

Looking at market evolution data:

| Year Range | Key Milestone | Market Size (USD Billion) | CAGR (%) | Driving Factor |

| 1980s-1990s | Emergence of CNC and early 3D printing | 0.5 (early adoption) | N/A | Prototyping basics |

| 2000s-2010s | First hybrid prototypes | 5.2 | 15 | Material advancements |

| 2020-2024 | AI integration begins | 15.39 | 20 | Pandemic-driven localization |

| 2025-2030 | Full AI-driven hybrids | 16.16 to 35.79 | 23.5 | Sustainability and efficiency |

| 2030-2035 | IoT and global scaling | Projected 195.6 | 22.13 | Mass customization |

| Beyond 2035 | Quantum-enhanced optimization | Estimated 500+ | 15+ | AI-IoT convergence |

This table highlights the explosive growth, underscoring hybrid’s role in rapid prototyping’s future.

Precision Boost: How CNC Fusion Strengthens Durability in Rapid Prototyping

One of the standout perks of hybrid manufacturing in rapid prototyping is the precision boost it delivers. CNC’s subtractive finesse polishes off the rough edges of 3D-printed parts, achieving surface finishes as smooth as Ra 0.8μm—perfect for prototypes that need to withstand real stresses. This fusion can enhance part strength by 30%, as CNC refines critical areas while 3D printing handles the bulk geometry.

In practice, this means prototypes that aren’t just mockups but functional testers. For aerospace engineers, hybrid rapid prototyping allows for lightweight yet robust components, reducing weight by 20% without sacrificing integrity. The key is in the workflow: print the base, machine the details, and iterate quickly.

But don’t take my word for it—data from comparative analyses shows clear wins:

| Metric | Pure CNC | Pure 3D Printing | Hybrid Approach |

| Tolerance Achieved | ±0.005mm | ±0.1mm | ±0.01mm (optimized) |

| Surface Roughness (Ra) | 0.4-1.6μm | 6.3-25μm | 0.8-3.2μm |

| Strength Improvement | Baseline | -20% vs. machined | +30% over additive alone |

| Iteration Time | 5-7 days | 1-2 days | 2-3 days |

| Failure Rate in Testing | Low (5%) | Medium (15%) | Very Low (3%) |

| Scalability for Complexity | Limited for organics | High | Very High |

These figures, drawn from industry tests, prove hybrid’s edge in durable rapid prototyping. It’s like giving your prototypes a superpower—precision that endures.

Cost and Sustainability Optimization: The Economic Green Path for Rapid Prototyping

Hybrid manufacturing isn’t just about tech—it’s a smart business move for rapid prototyping. By bridging prototype to production, it can slash costs by 20-50% for low-volume runs, as you avoid separate setups for printing and machining. This “prototype-to-production” model accelerates cash flow, letting small teams compete with big players.

On the green side, hybrids promote sustainability by cutting waste—additive builds near-net shapes, subtractive trims minimally, achieving zero-waste in optimized setups. This aligns with ESG goals, especially in reshoring supply chains amid global tensions. In the US, for instance, hybrid adoption is boosting local manufacturing, with a projected 4% rise in exports by 2025.

Here’s a sustainability and cost breakdown:

| Factor | Traditional Methods | Hybrid Manufacturing | Impact on Rapid Prototyping |

| Material Waste (%) | 70-90 | 10-20 | Reduces environmental footprint |

| Energy Consumption (kWh per Part) | High (50+) | Medium (20-30) | 40% savings in efficiency |

| Cost per Prototype (USD) | 500-2000 | 300-1000 | 20-50% reduction |

| Carbon Footprint (kg CO2) | 10-15 per part | 5-8 per part | Aligns with ESG standards |

| Lead Time (Days) | 7-14 | 2-5 | Faster market entry |

| Recycling Potential | Low (material scraps) | High (powder reuse) | Promotes circular economy |

This data underscores hybrid’s role in eco-friendly rapid prototyping, making it a win for profits and the planet.

Case Study Breakdown: Hybrid Innovations in Aerospace Rapid Prototyping

Let’s get real with a deep dive into aerospace, where hybrid manufacturing is soaring in rapid prototyping. Take the example of lightweight engine components: companies 3D print titanium brackets and CNC finish mating surfaces, cutting weight by 25% and development time by 40%. This isn’t theory—it’s certified for flight, showing how hybrids enable rapid iteration without compromising safety.

In medical devices, hybrids craft custom implants: 3D printing porous scaffolds for bone integration, then CNC machining precise fits. A 2025 case highlights a hip prosthesis prototyped in days, with 30% better osseointegration.

Consumer electronics? Suppliers use hybrids for phone casings with embedded sensors, blending aesthetics and function seamlessly.To map these successes:

| Industry | Case Example | Key Benefit | Time Savings (%) | Cost Reduction (%) | Outcome |

| Aerospace | Engine brackets | Lightweight design | 40 | 25 | Flight-certified prototypes |

| Medical | Hip implants | Custom osseointegration | 50 | 30 | Improved patient outcomes |

| Automotive | EV components | Multi-material efficiency | 35 | 20 | Faster R&D cycles |

| Consumer Electronics | Phone casing prototypes | Embedded features | 45 | 15 | Rapid market testing |

| Defense | Drone components | Complex geometries | 60 | 40 | Enhanced durability |

| Robotics | Robotic parts | Strength in motion | 30 | 25 | Iterative functional tests |

These cases illustrate hybrid’s transformative power in rapid prototyping across fields.

Tackling Challenges: Software Integration Pain Points in Hybrid Rapid Prototyping Workflows

No innovation is without hurdles, and hybrid manufacturing in rapid prototyping has its share. Software integration tops the list: bridging CAD files between 3D printing and CNC systems can lead to compatibility issues, causing delays or errors. For example, mismatched toolpaths might result in 10-15% rework rates in early adopters.

Skill gaps are another: teams need training in AI-driven programming, with IoT adding complexity for real-time monitoring. Yet, solutions are emerging—cloud-based platforms streamline workflows, reducing integration time by 60%.

Addressing these head-on ensures smooth rapid prototyping, turning potential pitfalls into opportunities for growth.

FAQ

What is hybrid manufacturing in the context of rapid prototyping?

Answer: Hybrid manufacturing combines CNC machining (subtractive) and 3D printing (additive) to create prototypes with unmatched precision and speed. In rapid prototyping, this fusion allows you to 3D print complex shapes and CNC finish critical features, reducing waste by up to 70% and iteration time from weeks to days. It’s ideal for functional prototypes in industries like aerospace and medical devices.

How does CNC enhance rapid prototyping compared to 3D printing alone?

Answer: CNC machining brings high precision (±0.01mm tolerances) and durability to rapid prototyping, refining 3D-printed parts for smoother surfaces (Ra 0.8μm) and 30% stronger components. Unlike 3D printing’s focus on speed and complexity, CNC ensures prototypes meet rigorous testing standards, making it perfect for load-bearing parts in automotive or robotics.

What are the cost benefits of using hybrid manufacturing for rapid prototyping?

Answer: Hybrid manufacturing cuts costs by 20-50% for low-volume runs by streamlining the prototype-to-production process. By combining additive and subtractive methods, it avoids separate setups, reducing costs from USD 500-2000 to USD 300-1000 per prototype. This efficiency accelerates cash flow, especially for startups and small teams.

How does hybrid manufacturing support sustainability in rapid prototyping?

Answer: Hybrid approaches minimize waste (10-20% vs. 70-90% in traditional methods) by using 3D printing for near-net shapes and CNC for minimal trimming. This reduces the carbon footprint by 5-8 kg CO2 per part and supports ESG goals, aligning with the 2025 trend of reshoring sustainable supply chains in the US.

What industries benefit most from hybrid rapid prototyping?

Answer: Aerospace, medical, automotive, consumer electronics, defense, and robotics see significant gains. For example, aerospace achieves 25% lighter engine components with 40% faster development, while medical prototyping delivers 30% better osseointegration for implants. These industries leverage hybrid’s precision and speed for rapid innovation.

You may also read: Legal Troubles, Controversies, and the Downfall of an Empire