The Marley Dry Ridge System has fundamentally transformed how roofing is approached in the UK, moving away from the outdated and often problematic mortar-based methods. Traditionally, ridge tiles were secured using a sand and cement mix, which is prone to cracking due to thermal expansion and weather exposure. The Marley Dry Ridge System, specifically the Universal RidgeFast technology, offers a mechanically fixed solution that ensures your roof remains maintenance-free and structurally sound for decades.

As extreme weather becomes more common, homeowners and contractors are shifting towards dry-fix solutions. This system is not just about aesthetics; it is a high-performance engineering marvel designed to protect the most vulnerable part of your roof—the ridge. By using a combination of high-grade aluminium flashing and a hydrophobic membrane, Marley provides a weather-tight seal that mortar simply cannot match. In this guide, we will delve deep into why this system is the industry benchmark and how it can save you significant repair costs over time.

Beyond durability, the Marley system addresses one of the biggest hidden killers of roof structures: condensation. Without proper airflow, moisture builds up in the loft space, leading to timber rot and mould. The RidgeFast system is engineered to provide continuous 5mm ventilation along the ridge line, meeting modern building regulations while keeping your home “breathing” and healthy.

What is the Marley Dry Ridge System? (Technical Deep Dive)

The Marley Dry Ridge System is a comprehensive, mortar-free kit designed for securing ridge tiles. Unlike traditional methods, this is a mechanical fix system, meaning every component is screwed or nailed into the roof structure. This complies with BS 5534 (the British Standard for slating and tiling) and BS 8612 (the performance requirements for dry-fix systems), ensuring that your roof can withstand the highest wind loads recorded in the UK.

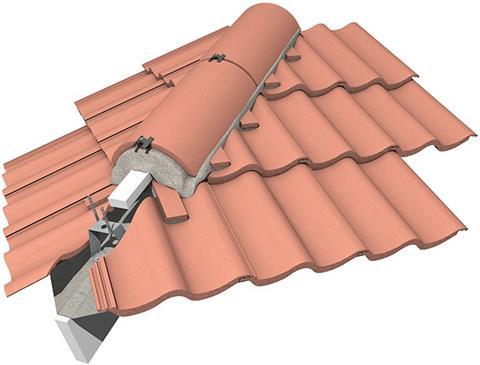

At its core, the system utilizes the RidgeFast technology. It consists of a ventilated ridge roll that sits beneath the ridge tiles, providing a barrier against rain and insects while allowing air to escape. The kit includes bespoke batten brackets that anchor the entire system to the roof’s timber rafters, providing a solid foundation that mortar bedding lacks. This level of security is why the National House Building Council (NHBC) now mandates mechanical fixing for all new roof installations.

Furthermore, the system is designed to be “Universal.” Whether you are using concrete tiles, clay tiles, or natural slates, the Marley system is adaptable. It works seamlessly with a wide range of pitches, generally between 12.5° and 60°, making it one of the most versatile dry-fix solutions available on the market today.

Understanding the Kit Components: What’s Inside the Box?

When you purchase a Marley Universal RidgeFast 6-metre pack, you aren’t just getting a roll of plastic; you are getting a precision-engineered kit. Understanding these components is crucial for a successful installation and for appreciating the value of the system. A standard 6m kit (Product Code: MA53300) typically contains the following:

- 6m Ridge Roll: Features a high-grade aluminium flashing and a hydrophobic membrane for maximum weather resistance.

- 10 x Batten Brackets: These are bespoke brackets used to anchor the ridge batten to the main roof structure.

- 13 x Ridge Unions & Clamps: These components sit between the ridge tiles, ensuring they are spaced correctly and held down securely.

- Stainless Steel Screws (75mm x 4.8mm): Used to fix the ridge tiles through the unions into the batten.

- Stainless Steel ARS Nails: Specifically designed for fixing the batten brackets.

The use of stainless steel is a critical detail. Unlike standard galvanized nails that may rust over 20 years, stainless steel ensures that the mechanical fix remains intact for the entire lifespan of the roof tiles. This attention to detail is what justifies the price point of the Marley system compared to cheaper, generic alternatives.

How the Marley Dry Ridge System Works: Performance & Ventilation

Installing the Marley Dry Ridge System is relatively straightforward, though proper preparation and attention to detail are necessary for optimal results. The first step in the installation process is ensuring you have the correct materials, which typically include ridge tiles, batten brackets, dry ridge system kits, nails, and essential tools like a hammer and spirit level. The batten brackets should be installed along the ridge line, securing them tightly to the roof structure to provide a strong base for the ridge tiles.

Once the batten brackets are in place, position the ridge tiles over the brackets, ensuring they are aligned correctly and securely fastened. It is essential to check the alignment of the tiles using a spirit level to ensure they are straight and even. This simple but crucial step will ensure the ridge tiles remain properly fixed for years to come. The dry ridge system significantly reduces the risk of leaks and provides better ventilation, ensuring the roof is secure and weather-resistant for the long haul.

Marley Dry Ridge System Prices

One of the key considerations when deciding whether to install the Marley Dry Ridge System is the cost. While the initial price of the system might seem higher than traditional mortar bedding, it is important to consider the long-term savings. The Marley Dry Ridge System is a cost-effective solution, as it requires little maintenance and significantly reduces the likelihood of needing repairs or replacements in the future. The price of the Marley Dry Ridge System typically starts at around £140 for a 6-metre pack, but this can vary depending on the size and complexity of the roof. Additional costs may include batten brackets and any specific accessories required for your roof type.

When compared to traditional mortar bedding, the Marley Dry Ridge System proves to be a more economical choice in the long run. Not only do you save money on maintenance and repairs, but the system’s quick installation also helps save on labour costs. Furthermore, its durability and weather resistance mean that you won’t have to worry about the roof’s performance during harsh weather conditions. As a result, the Marley Dry Ridge System represents great value for homeowners seeking a reliable and cost-effective roofing solution.

Advantages of Using the Marley Dry Ridge System

There are numerous advantages to using the Marley Dry Ridge System over traditional roofing methods. One of the primary benefits is its durability. Unlike mortar bedding, which can crack and require ongoing repairs, the Marley Dry Ridge System remains intact for years without the need for maintenance. The system is also highly weather-resistant, ensuring that it can withstand extreme conditions such as heavy rain, wind, and snow.

Another significant advantage is the system’s ability to improve roof ventilation. Proper ventilation is crucial for preventing moisture build-up within the roof space, which can lead to dampness, mould, and timber damage. The Marley Dry Ridge System ensures continuous ventilation along the ridge, reducing the risk of moisture accumulation and improving the overall health of your roof. This feature also helps to extend the life of your roofing structure and reduce the likelihood of costly repairs in the future.

Conclusion

The Marley Dry Ridge System offers a modern, cost-effective solution for securing ridge tiles and ensuring long-lasting roof performance. Its dry-fix design eliminates the need for mortar, providing enhanced durability and weather resistance. The system is quick and easy to install, and its ability to improve roof ventilation makes it a wise investment for homeowners looking for a reliable roofing solution. The Marley Dry Ridge System not only saves time and money but also enhances the overall stability of your roof, providing peace of mind for years to come.

Whether you’re building a new roof or replacing an old one, the Marley Dry Ridge System is an excellent choice for both residential and commercial properties. Its advantages, including reduced maintenance, increased durability, and improved ventilation, make it a standout option for any roofing project. With a solid reputation for quality and reliability, the Marley Dry Ridge System ensures that your roof remains secure, weather-resistant, and long-lasting.

FAQs

The Marley Dry Ridge System uses a dry-fix method, securing ridge tiles with mechanical fasteners and bespoke brackets, whereas mortar bedding requires the use of mortar that can crack and deteriorate over time.

The Marley Dry Ridge System is designed to last for many years without the need for repairs, providing long-term security and durability compared to traditional roofing methods.

While experienced DIYers can install the Marley Dry Ridge System, it is recommended to hire a professional roofer for optimal results and to ensure proper installation.

You will need batten brackets, ridge tiles, a dry ridge system kit, nails, and basic tools such as a hammer and spirit level.

The cost typically starts at around £140 for a 6-metre pack, with additional costs for necessary accessories and installation based on the roof’s size and complexity.

Yes, the Marley Dry Ridge System is compatible with most standard ridge tiles, making it versatile for different roofing materials.

Yes, the system works on roofs with pitches between 12.5° and 60°, making it ideal for a wide range of roof types.

The dry ridge system offers improved weather resistance, long-lasting durability, enhanced ventilation, and reduced maintenance costs compared to traditional methods.

You may also read: What Makes the Best Ground Coffee for Cafetiere UK?