When selecting a PCBA supplier, understanding industry standards is crucial to ensuring the right quality level for your product. Whether you’re evaluating a PCB prototype or preparing for full-scale production, IPC-A-610 standards provide the foundation for defining acceptable workmanship. Specifically, IPC-A-610 Class 2 and Class 3 are two commonly used quality classes that serve different product reliability needs. Choosing the correct class impacts not only performance and reliability but also manufacturing cost, lead times, and supply chain risk.

What Is IPC-A-610 and Why It Matters

IPC-A-610, published by the IPC (Association Connecting Electronics Industries), is the globally recognized standard defining acceptability for electronic assemblies. This standard outlines criteria for component placement, solder quality, board damage, cleanliness, and more. Its purpose is to ensure that assemblies meet functional and reliability requirements across industries—from consumer electronics to aerospace.

For a PCBA supplier like PCBasic, adherence to IPC standards is not just about compliance—it’s about delivering consistent, high-quality products that align with customers’ expectations and end-use requirements. The two most referenced classes in IPC-A-610 are Class 2 and Class 3, each designed for different risk profiles and application environments.

IPC-A-610 Class 2: Standard Quality for Commercial Applications

Class 2 is often referred to as the “general electronic products” category. This class is suitable for applications where continued performance and reliability are important but occasional failures are not catastrophic. Typical use cases include:

• Consumer electronics

• Industrial control systems

• Office equipment

• Telecommunications devices

Key Characteristics of Class 2

• Moderate defect tolerance: Minor cosmetic imperfections that don’t affect performance are acceptable.

• Balanced cost and reliability: Designed for products where cost efficiency and time-to-market are priorities.

• Suitable inspection criteria: Solder joints and components must meet functional requirements but may have looser cosmetic constraints than Class 3.

In summary, Class 2 is ideal for mid-range products where failure is undesirable but not life-threatening. It strikes a balance between quality and affordability.

IPC-A-610 Class 3: Highest Level for Mission-Critical Products

Class 3 represents the most stringent set of criteria defined in IPC-A-610 and is typically reserved for high-reliability applications. This includes industries where failure is unacceptable and could result in severe safety, financial, or operational consequences.

Common Class 3 Applications

• Aerospace and defense systems

• Medical devices

• Automotive safety systems

• High-frequency communication infrastructure

What Makes Class 3 Different

• Stricter workmanship requirements: No visible defects are tolerated. Component placement, solder fillets, and finishes must be nearly perfect.

• Enhanced inspection: Visual and automated inspection practices are more rigorous.

• Higher reliability demand: Products must withstand more demanding environments, including extreme temperature and vibration.

Because of these requirements, Class 3 products often involve more time, advanced inspection technologies, and higher assembly costs—but with a corresponding increase in reliability and longevity.

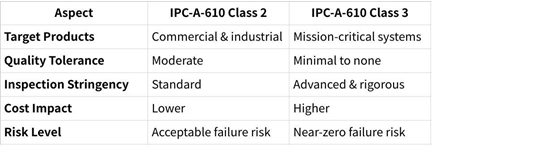

Comparing Class 2 vs Class 3: A Practical Summary

Choosing the Right Standard for Your Project

When deciding between Class 2 and Class 3, start by evaluating the end-use environment of your product:

1. What are the consequences of failure?

○ Non-critical? Consider Class 2.

○ Critical or safety-related? Choose Class 3.

2. What is your reliability requirement?

○ Standard commercial reliability = Class 2

○ High performance under stress = Class 3

3. How does cost factor into your design?

○ If cost sensitivity is high and application risk is low, Class 2 is appropriate.

○ For mission-critical designs where risk mitigation outweighs cost, Class 3 is essential.

Engaging with a PCBA supplier early in the design process ensures your design, prototype, and production standards align with IPC requirements. PCBasic’s experience with both Class 2 and Class 3 processes helps you optimize the balance between quality, cost, and reliability from your first PCB prototype to full production volumes.

Conclusion

Understanding the differences between IPC-A-610 Class 2 and Class 3 is fundamental for successful PCB assembly. While Class 2 serves most everyday electronics with a balanced approach to cost and quality, Class 3 is the choice for high-stakes, high-reliability products. By matching the assembly standard to your product’s needs and working closely with a knowledgeable PCBA supplier like PCBasic, you can make informed decisions that support both performance and budget goals.